100 years of Dietz-motoren

April 27, 2022

This year we can look back on 100 years of company history.

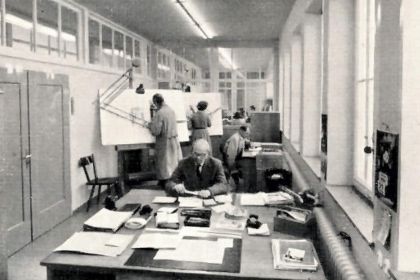

Back in 1922, Dietz-motoren was founded by master mechanic Adolf Dietz. Since that time, we are deeply rooted in Dettingen unter Teck. In a rented workshop, collectors for generators and starters were initially manufactured on a contract basis. In 1925, the company was able to purchase its own building at Kirchheimer Strasse 109 and one year later, in 1926, began manufacturing electric motors and blowers. The company experienced continuous growth, so it had to be extended and expanded again and again.

In the following two decades, the young company continued to develop purposefully. As a result of the dynamic development after the currency reform and the strong demand, the premises were soon no longer enough. So in 1958, the construction of plant II in the industrial area of Dettingen was started, where the focus of production is still today. In the early 1960s, a branch plant was opened in Heroldstatt-Ennabeuren. For years, mainly windings for motors were manufactured there by hand. In the meantime, the mechanical processing and assembly of radial fans is located there. Today, the entire production is located in these two plants, whose production areas have been enlarged several times over the years.

In 1960, our company founder Adolf Dietz passed away. From very small beginnings, he created a company that has now existed for 100 years. For many years, the sons-in-law of the company founder, Dr. Willy Hub, Hartmut Müller and Hans Bauer, were responsible for the further development of the company. The successor generation has single-mindedly developed his work further, true to his motto "Success through quality". Dietz-motoren is now in its third generation and remains a partnership to this day.

Today, we offer a wide range of electric motors, generators and radial fans, as well as the associated control electronics, which meet all requirements in terms of efficiency, lifetime costs and legal requirements.

According to the motto "Innovation needs production", all relevant value-added processes required for the production of electric motors and radial fans can be manufactured in-house. The special focus is on the electrical core components of the electric motors - here the entire manufacturing process of the components is produced with modern machinery.

We will continue to invest in modern development and manufacturing processes in order to meet growing market requirements. Customized solutions in particular require close cooperation with the customer on the part of the development department.

Essentially, leading machine builders all over the world are served, with a focus on the textile, ventilation technology, food technology and regenerative energy sectors.

For product safety and to prove the agreed function, all necessary tests and simulations can be carried out in our own development and test field.

We have made rapid progress in the area of digitalization over the past few years. In 2018, we not only brought the specially designed product finder "Fanfinder" online, but also, just one year later, the Online Shop for radial fans. Through our in-house online shop, we are now able to ship the radial fans we have in stock to our customers within the shortest possible time and to react quickly.

Through the knowledge and skills of almost 270 highly qualified and motivated employees, the production of high-quality products of the highest quality is implemented. True to Adolf Dietz's motto: "Success through quality", qualified employees play a key role in this process, which is taken into account with permanent training and further education.

We train our young generation ourselves and the apprentices complete their training with above-average success. Currently, we employ about 15 apprentices in the technical and commercial area and it is the declared goal, as in the past, to take over all apprentices.