By means of mass inertia a separation of substances takes place in the centrifuge.

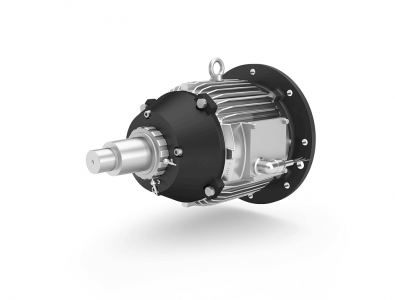

We offer drive motors here, with B-side flange mounting and optional speed monitoring. Depending on the application, special attention is paid to the bearing of the rotor. This is appropriately dimensioned and guided in grey cast iron end shields.

The special features of the electrical design, keyword "heavy starting", for mains or frequency converter operation should be emphasized. Particularly resilient insulation of the winding and rotors with silumin cages ensure the appropriate behaviour of the motor under such heavy loads during start-up operation.

On our electric motors page you will find information about our electric motors, suitable for your machine concept. Or simply get in touch with one of our employees.

Endless possibilities and flexibility in every component - process-integrated, heavy-duty cast iron end shields, flanges and stators with winding (Current-UV-impregnated) In addition to standard connections via terminal box, Dietz-motoren also offers motor connections via industrial connectors.